1. General teatures & merit

- Approximate cycle time : 8 Batteries / Min. of LN3 Battery

- 1st station for acid filling, 2nd station for acid leveling and 3rd station for level checking

- 2 batteries per cycle for 1 X 6 type battery

- Timer control for filling acid into battery container so that acid amount can be adjusted per each cell.

- Acid filling nozzle of special material for easy maintenance

- Even pressure in acid filling using main acid tank and sub acid tank

- Individual control of acid filling amount of each cell

- Acid filling by gravity, not using pump

- No acid dripping on the cover after filling

- No need for changing tool while changeover

- Easy adjustment in setting nozzle distance while changeover

- Using vacuum pump for suction process and the pump is designed not to let acid enter into the pump

- Using 2 probes of hastelloy-C material for level check

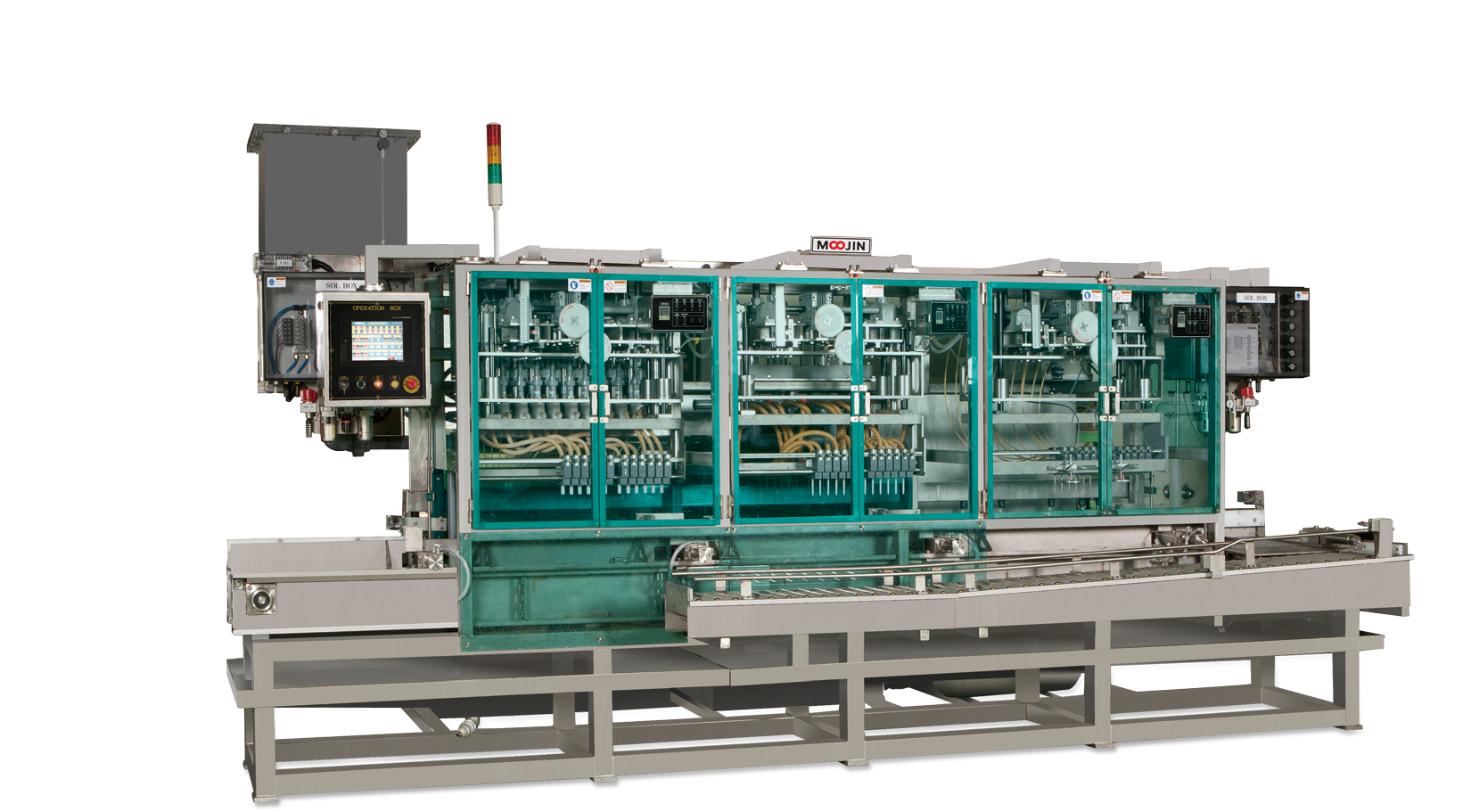

2. Machine details

- Applicable battery size : L185 - 410, W125 - 180, H170 - 250 (in mm)

- Conveyor belt : PVC belt

- Safety cover included

- Air part : SMC

- Main power : 3kW

- Control PLC : MITSUBISHI (USER OPTION)

- Approx. size & weight : L3,700 × W2,400 × H1,600mm / 2,500kg

3. Utility

| Standard electrical power | 220 / 380 / 440V * 3-phase * 50 / 60Hz (USER OPTION) |

|---|---|

| Compressed air | 5 ~ 6kg / ㎠ |