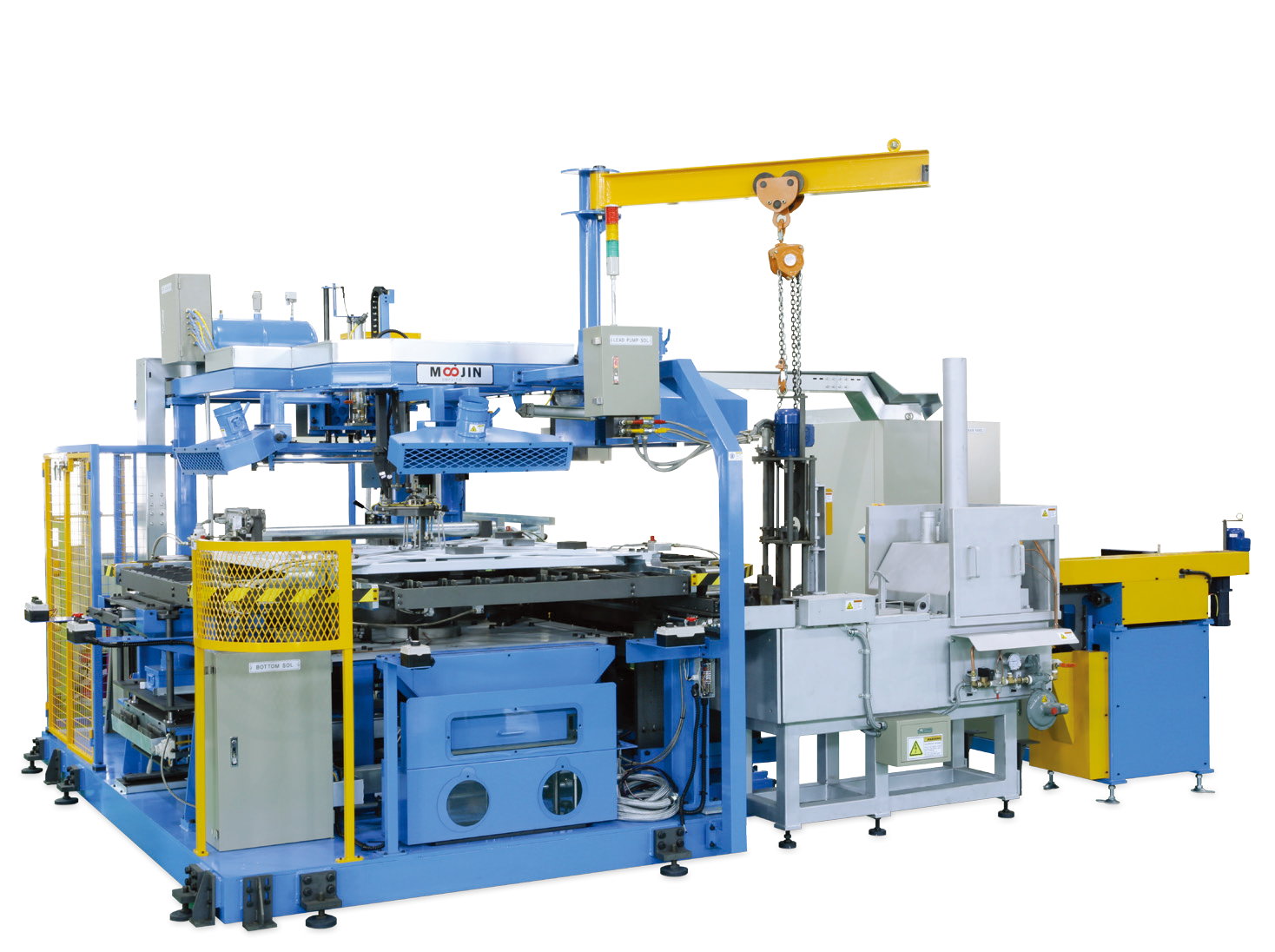

MOOJIN CAST ON STRAP

1. General teatures & merit

- Cycle Time : Approx. 1.5~2 Batteries / Min. based on N200 (8D) Battery (6 cells / cycle)

- Semi Automatic Operation

· Manual : Loading / Unloading Station

· Auto : Aligning, Lug brushing, Fluxing, Drying and Molding Station

- Battery type Changeover : Approx. 15 minutes

2. Machine details

- Applicable battery size : L310 - 525 W168 - 278, H200 - 250 (in mm)

- Air part : SMC

- Main power

· Motor : 1.5kW

· Mold : 18kW

· Melting pot : 24kW

- Control PLC : MITSUBISHI, Touch screen : PROFACE or MITSUBISHI

- Sensor : KEYENCE, OMRON, MITSUBISHI (USER OPTION)

- Approx. size & weight : L3,200 × W2,500 × H2,500mm / 7,000kg

3. Detail information of each process

• 1st station (Loading)

- Manual loading of plates into jig box

• 2nd station (Aligning, Brushing, Fluxing and Drying)

- With vibration table ass’y & automatic top lug align unit

- Using servo system for adjusting the height of the vibration table according to the various height of plates.

• 3rd station (Molding)

- Using servo motor for precise control of depth of lug in strap and also of the movement (timing of dipping and dipping speed)

• 4th station (Unloading)

- Lifting up plate groups from jig box for operator to take them out more easily.

4. Utility

| Standard electrical power | 220V / 380V / 440V * 3-phase * 50 / 60Hz(USER OPTION) |

|---|---|

| Compressed air | 5 ~ 6kg / ㎠ |

| Cooling water | 2 ~ 4kg / ㎠ |