MOOJIN CAST ON STRAP

1. General teatures & merit

- Cycle Time

· AGM : Approx. 2-3 Batteries / Min. based on LN3 Battery

· PE : Approx. 2-3 Batteries / Min. based on LN3 Battery

- Full automatic operation

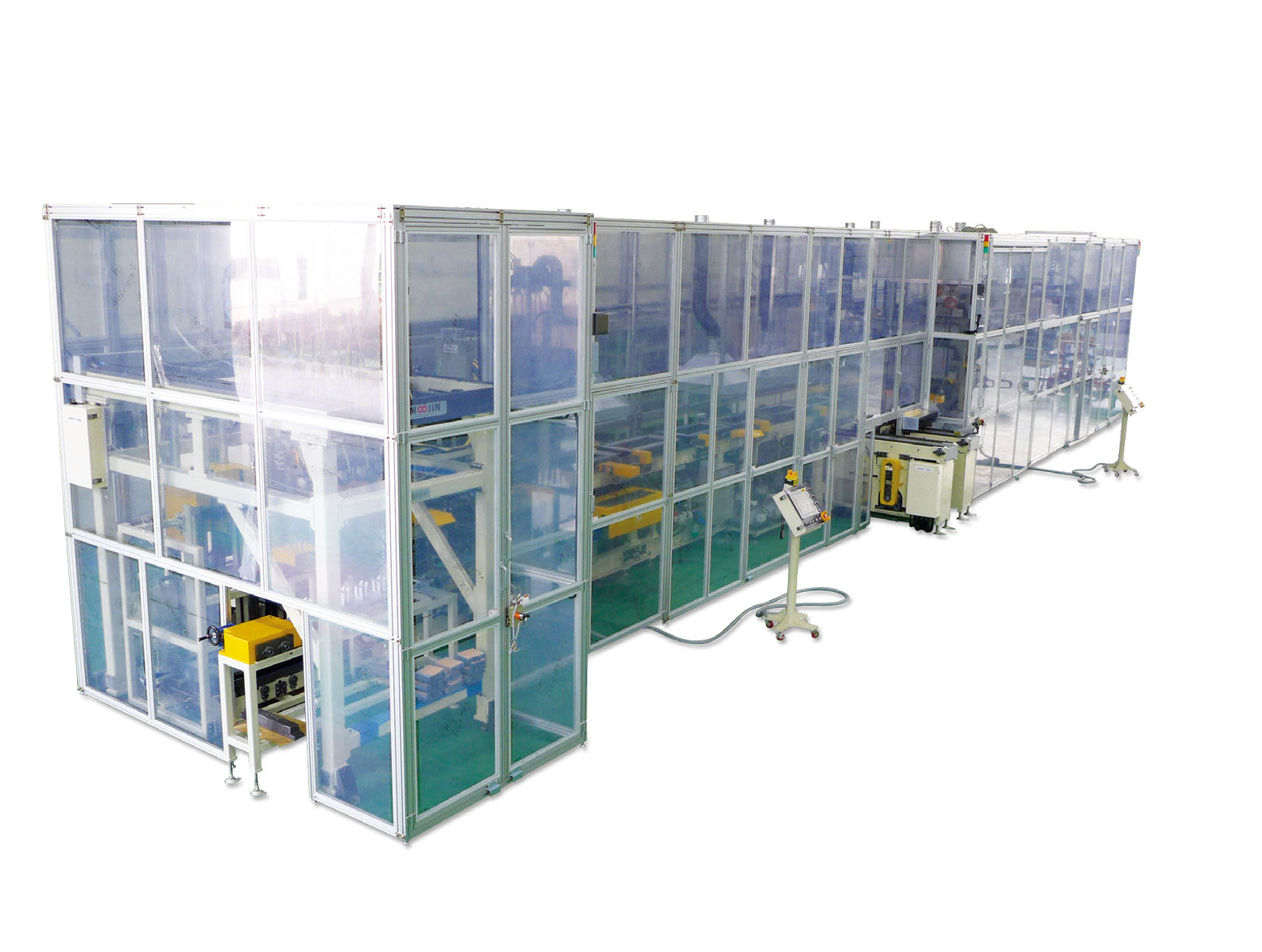

2. Machine details

- Applicable battery size : L180 - 345, W125 - 185, H170 - 230 (in mm)

- Air part : SMC

- Main power

· Motor : 25kW

· Mold : 36kW

· Melting pot : 36kW

· Preheat mold : 36kW

- Melting furnace : Electric furnace

- Control PLC : MITSUBISHI, Touch screen : PROFACE or MITSUBISHI

- Sensor : KEYENCE, OMRON, MITSUBISHI (USER OPTION)

- Approx. size & weight : L19,000 × W3,300 × H3,500mm / 26,000kg

3. Detail information of each process

• 1st STATION : Loading

• 2nd STATION : Vibrating Table Ass’y, Lug Align and Group Align

• 3rd STATION : JIG BOX Rotation by 180° & Lug Cutting

• 4th STATION : Lug Brush

• 5th STATION : Fluxing

• 6th STATION : Drying & Lug Bending

• 7th STATION : Tinning

• 8th STATION : Fluxing

• 9th STATION : Drying

• 10th STATION : Stand by Station

• 11th STATION : Dual Lead Feeding type CAST ON STRAP Mold Stations with Mold Preheater of Elevator type, Dual Lead Feeding system for POS. and

NEG. and GANTRY TYPE MOLD TRANSFER UNIT with 2 HEADS including Hoist for changing Lead Pump and Holding Pots

• 12th STATION : Spool Brush for Strap

• 13th STATION : JIG BOX Rotation by 180°

• 14th STATION : Strap Check

• 15th STATION : Gantry type AUTOMATIC UNCLAMPING & UNLOADING from JIG BOX and AUTOMATIC INSERTION including Container Feeding Conveyor,

Discharging Conveyor and Reject Conveyor before entering Connection Conveyor

• 16th STATION : JIG BOX Returning

4. Utility

| Standard electrical power | 220 / 380 / 440V * 3-phase * 50 / 60Hz (USER OPTION) |

|---|---|

| Compressed air | 5 ~ 6kg / ㎠ |

| Cooling water | 2 ~ 4kg / ㎠ |