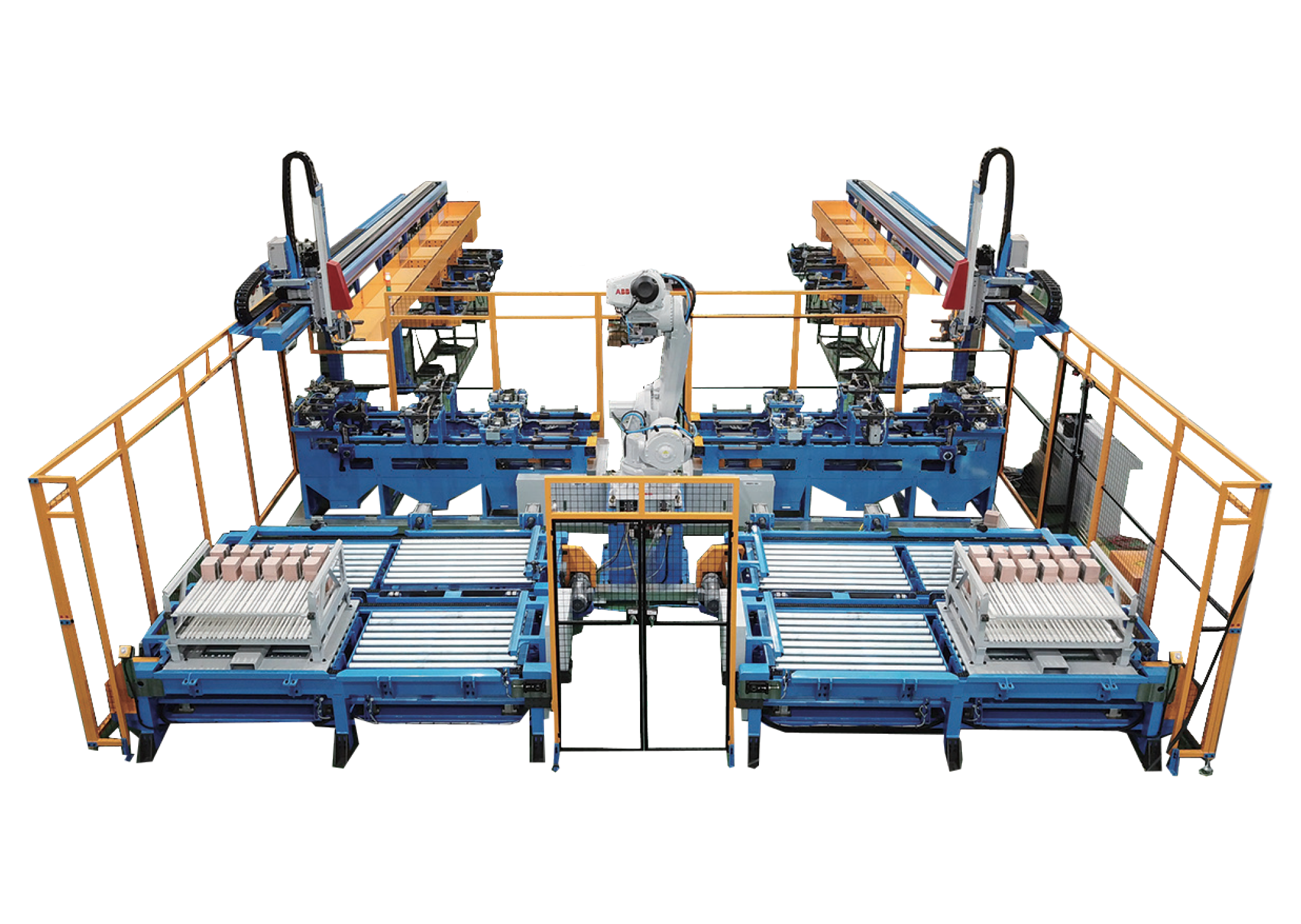

1. General teatures & merit

- Cycle Time : Up to 460 plates / Min. (depends on plate stack height)

- Full automatic operation in each station

2. Machine details

- Applicable plate size : W85-170, H99-150(Including Lug height) (in mm)

- Air part : SMC, FESTO(USER OPTION)

- Main power : 50kW

- Control PLC : MITSUBISHI, Touch screen : PROFACE or MITSUBISHI

USER OPTION : ALLEN BRADLEY, SIEMENS and other Brands

- Sensor : KEYENCE, OMRON, MITSUBISHI (USER OPTION)

- Approx. size & weight : L21,000(14,000) x W8,600 x H3,800mm / 18,000kg

L21,000 - The space required including Enveloper. L14,000 - Feeder system itself.

3. Detail information of each process

• 1st Station : Pallet(Rack) feeding part

• 2nd Station : Robot part

Move the plate stack from 1st Station(feeding) to 3rd Station(moving)

• 3rd Station : Plate stack moving part

Move the plate stack to gantry part

Plate stack alignment / 180° rotation for lug positioning / tilting(90° Rotation) / separate sticked plates & alignment

• 4th Station : Plate group transfer to feeder part of Enveloper

• 5th Station : Plate feeding part

Plate feeding into Enveloper

4. Utility

| Standard electrical power | 220V / 380V / 440V * 3-phase * 50 / 60Hz(USER OPTION) |

|---|---|

| Compressed air | 5 ~ 6kg / ㎠ |